Home page Who we are Products Services Technology INERJET R&D Press Contact us

ATSENTI in collaboration with

CANMET ENERGY

A Brief History:

The CANMETENERGY Research Centre (Natural Resources Canada) is Canada’s leading technological research and development organization in the field of clean energy. Here are just a few facts showing the breakthroughs and achievements of Atsenti in this area:

- Expertise in new and innovative compact spray-drying technology in relation to inert carrier particles (US Patent # US 6,993,856 B2);

- In 2010, exclusive site licence and exclusive worldwide licence issued to Atsenti for its new technology;

- In 2011, Atsenti founded the INERJET Technological Development Centre.

- In 2016, new complete patent (US Patent #2016/0331005 A1)

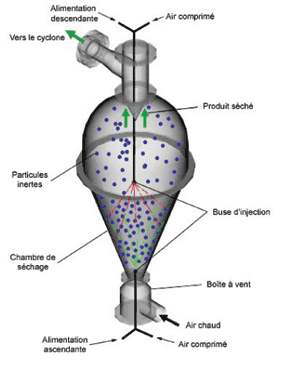

The following diagram shows an overview of the drying process, which is essentially based on the transfer of the heat accumulated in inert carrier particles to the humid material by conduction, as well as convection of the ascending hot air.

The approach consists of delivering a stream of ascending hot air, which causes an intense agitation of the inert carrier particles, while transferring the heat they have accumulated.

Then, the product is atomised into fine droplets, which coats the inert carrier particles that function as heat storage and an intermediate drying medium between the hot air and the liquid product.

The ideal drying cycle is based on four successive steps:

- The heating of inert carrier particles;

- The coating of inert carrier particles by fine droplets;

- The drying of the coating formed on the inert carrier particles, followed by the cracking caused by their collision within the dryer;

- The disengagement of the dry coating and the subsequent push of the dry product, now in the form of uniform particle-size powder, towards the cyclone, so that it may be separated from the air and recovered.

Based on its physical and biological properties, the liquid supply could be inserted into the dryer from above as well as below. This drying method makes it possible to dry products at lower temperatures than more conventional spray dryers. This method presents key advantages:

- Small and Medium Enterprises (SME) in the Agri-Food, pharmaceutical and natural health industries have another option when it comes to transforming liquid products into powders, using an ultra-compact system that offers many advantages over more conventional spray dryers;

- The compact dryers occupy less floor space and require less height, with no additional infrastructure and could represent up to 12% in overall energy savings;

- This dryer enables SMEs to transform their new products into an added-value powder of exceptional quality.